We’ll Provide a Custom Auger Conveyor That Delivers Unmatched Reliability

An auger conveyor, or screw conveyor, is often the choice for industrial plants that need to move liquid, semi-solid, or granular materials in a fast and efficient manner. It features a helical screw blade that propels the materials through a tube or a shaft at whatever rate is needed. While many different manufacturers offer industrial auger conveyors, none can match the customization options offered by the experts at Materials Handling Equipment (MHE). We have been custom-engineering conveyors since 1927 and can manufacture and install a system that meets your plant’s specific needs. Additionally, all of our conveyors exceed the standards of the Conveyor Equipment Manufacturers Association (CEMA), which we helped develop.

Customization Is Key

When you choose MHE to manufacture your auger conveyor, you won’t have to worry about the lost productivity that can result when you try to accomplish your goals using a standard-built, cookie-cutter conveyor. We’ll meet with your engineers to discuss your specific needs and review the location your auger conveyor will occupy, and we’ll custom engineer a perfect solution.

Some of the unique features our conveyors offer include:

- Capacities to 300 TPH

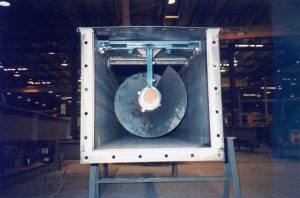

- Diameters of up to 6 feet

- Easy maintenance thanks to unique access points

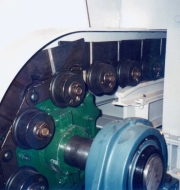

- Jig-welded construction for precise alignment

- Lengths up to 300 feet

- Inclines up to 60 degrees

- Heat resistance of up to 2,200 degrees Fahrenheit

- A variety of dust-tight shaft seals to prevent leaks

- Tubular, U-type, V-type, drop bottoms, box type, and split troughs

- Standard, ribbon, cut, and paddle flights

- Break-formed troughs and heavy-duty formed flanges

Offering Unmatched Durability

We have a reputation for manufacturing some of the most durable and reliable conveyors on the market, and it’s a distinction that we take pride in. It’s a status that’s well-earned, as many of our conveyors are still performing reliably on a daily basis more than a half-century after we initially delivered them. So, why do our auger conveyors last so long? It’s simple—we utilize wear-resistant alloys and heavy-duty components that can withstand the harshest conditions imaginable, including environments of extreme abrasion and corrosion and the highest temperatures. Our attention to detail during the manufacturing process ensures that your auger conveyor will perform efficiently, day after day and year after year.

Providing Comprehensive Service

When you partner with MHE, we’ll ensure that your plant is positioned to get the most out of your auger conveyor. We’ll ensure that the completed product is installed flawlessly, and we’ll take the time to train your employees on its operation and share the necessary safety protocols. And, if an issue ever arises, we have a 24-hour Critical Care team standing by to provide immediate assistance.

Schedule a Site Visit Today

If you are interested in a custom-engineered auger conveyor that will accomplish your plant’s goals without breaking your budget, contact Materials Handling Equipment today to schedule a site visit and consultation. We look forward to adding your company to our long list of satisfied customers that consistently turn to us for all of their conveyor needs.