Custom Bucket Elevators That Can Meet the Needs of Any Industry

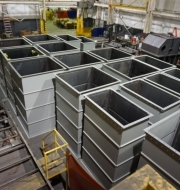

Since the 1920s, Materials Handling Equipment (MHE) has been engineering and manufacturing bucket elevators to meet the needs of every industry, including those that face challenges such as abrasion, corrosion, and extreme temperatures. We offer unmatched industry experience and are proud to note that many of our conveyors are still in operation more than a half-century after delivery. MHE custom designs bucket elevators based on each client’s specific job requirements, thus effectively reducing the costs incurred from purchasing mass-produced equipment with superfluous features.

MHE was one of the first companies to introduce the severe-duty class of bucket elevator conveyors and pioneered the cement class. We continuously research historical information and develop new techniques to improve the quality of our bucket elevators. Our unique designs help streamline bulk handling operations. For example, we utilize Ni-Hard gravity take-up bearings, which help increase service life. We also utilize custom components and wear-resistant alloys.

Types of Bucket Elevators

No matter what type of bulk materials you’re working with, or how extreme the environment is, we can manufacture a bucket elevator that meets your needs. Our bucket elevators can be continuous, centrifugal, or high-speed, and can have multiple drive arrangements. Classifications include:

- Industrial duty – Options include standard grade and food grade (belt type).

- Mill duty – These are industry-specific and can include options for wood chips or conveyors that operate at higher speeds (belt-type).

- Heavy duty – These bucket elevators are manufactured for severe conditions and utilize heavy-duty construction features. Hot lime is an example of the material that can be conveyed.

- Cement mill duty – These feature heavy-duty construction that allows for at least 20 years of service. They also come with special maintenance features.

- Severe duty – For special applications, we offer super-capacity and rubber-lined bucket elevators.

Materials Handled by Bucket Elevators

Industrial bucket elevators can move a variety of materials, including grains, fertilizers, aggregates, and powders. They are designed to handle both free-flowing and sluggish materials with ease. For heavy-duty applications, continuous bucket elevators are often the preferred choice, as they operate a lower speeds to keep the breakage of brittle materials to a minimum. They’re also favored for handling abrasive materials.

Centrifugal bucket elevators, which use a spinning action to discharge materials from the bucket, offer higher speeds and increased output, but they can impact product quality. If you’re trying to choose between a belt bucket elevator and a chain bucket elevator, your decision will depend on the product, the capacity needed, and the conveying height.

Specifications

The team at MHE will meet with your engineering team to learn about your facility’s needs and environment so we can customize a long-term solution. We’ll work with you through every step of the process, including the design, installation, and service. We can provide bucket elevators with the following specifications:

- Capacities up to 1500 TPH

- Heights up to 200+ feet

- Inclined models up to 60 degrees

- Temperatures up to 1200 degrees Fahrenheit

Some of the custom features we can utilize for your bucket elevator include:

- Hoist beam, service platform, and inching drive options

- An adjustable strike-off plate to prevent material fallback

- Top venting and lightweight split hoods

- Dust-tight shaft seals

- A reinforced head section and motor platforms with landing pads

- Special heavy-duty casing design features

- Adjustable bearing stops and leveling shim packs

- Easy-access doors and ports for maintenance and inspection

- Various belt and chain drive options

Our Process

We’ll go to great lengths to ensure that you’re happy with your bucket elevator as well as our service. We’ll visit your plant to see where the conveyor is needed and listen to your specific goals, and we’ll use that information to design and manufacture an ideal solution. When it’s time for your custom conveyor to be installed, we’ll ensure that it’s working correctly and that your employees are trained in its proper operation and safety protocols. However, our job doesn’t end there. If you ever experience an issue, even decades after installation and for conveyors we didn’t manufacture, our critical response team will jump into action to get your conveyor back online as soon as possible.

Invest in Precision: Find Your Custom Elevator Solution

Contact MHE today. We’d be happy to schedule a consultation to answer any questions you have about the heavy-duty bucket elevators we offer.