Custom Conveyor Solutions for Salt, Sand, and Other Abrasive Materials

Moving highly abrasive materials like salt, sand, and aggregates takes a serious toll on standard conveyor systems. These substances grind down metal surfaces, accelerate corrosion, and increase the need for costly maintenance. To keep production running smoothly, you need a conveyor system that’s built to withstand constant wear and tear—without constant downtime.

The Challenge of Abrasive Materials

Salt and sand are among the toughest materials to handle. Salt is both abrasive and corrosive, especially in humid or wet environments. Sand, gravel, and similar aggregates act like sandpaper, rapidly wearing down components that aren’t designed for heavy-duty use.

Beyond the direct damage, these materials often create secondary problems such as dust, spillage, and buildup, which can compromise safety and slow operations. A conveyor system that isn’t designed to manage these issues will struggle to perform over time.

What Makes an Abrasion-Resistant Conveyor?

Conveyor durability comes from smart engineering and the right materials. Key factors include:

- Wear-Resistant Materials – Hardened steel, replaceable liners, and corrosion-resistant coatings extend the life of high-contact components.

- Heavy-Duty Components – Chains, screws, buckets, and flights must be built to withstand repeated exposure to sharp, gritty materials.

- Custom Engineering – Systems should be tailored to the size, density, and flow rate of your material, as well as environmental factors like moisture and temperature.

- Dust and Spill Control – Sealed housings, covers, and improved flow designs minimize waste and improve worker safety.

These design elements work together to provide a conveyor system that resists wear, limits downtime, and delivers a longer service life.

Proven Conveyor Solutions from MHE

Since 1927, Materials Handling Equipment (MHE) has specialized in designing and manufacturing conveyors that excel in the toughest environments. Our systems are not off-the-shelf, they are built from the ground up for your specific process.

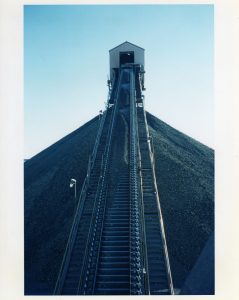

We’ve built custom conveyors for industries such as cement, steel, mining, power generation, and specialty chemicals, where equipment failure simply isn’t an option. From high-capacity bucket elevators moving salt in coastal environments to drag conveyors handling sand in aggregate plants, our designs are proven to perform.

Here are a few of the solutions that we frequently create:

- Bucket elevators

- Drag conveyors

- Screw conveyors

- Apron and pan conveyors

- Belt conveyors

- Fully custom solutions

Every system is engineered and manufactured in the USA, backed by nearly a century of craftsmanship and expertise.

Why Partner with MHE?

Every conveyor system is only as strong as the team behind it. With MHE, you gain a trusted partner dedicated to building equipment that outlasts the competition and supports your production goals. Here’s why businesses rely on our engineers:

- Experience with Abrasive Materials – Decades of projects handling salt, sand, clinker, ash, and other punishing bulk solids.

- Longer Lifespans – Our conveyors are built to perform, year after year.

- True Customization – No two systems are the same; we design for your material, your process, and your environment.

- Responsive Support – Our team works closely with you from concept to installation and beyond.

Reasons like these are why leading companies trust MHE to build solutions that can handle their toughest materials.

Get a Quote for Your Conveyor Project

When reliability matters most, turn to MHE. Our abrasion-resistant conveyors are built to handle salt, sand, and the most demanding bulk materials, without compromise. Contact us today to discuss your project and request a quote.

Pan conveyors are an indispensable tool for various industries, including cement manufacturing and power generation. Their ability to efficiently transport bulk materials, even under challenging conditions, makes pan conveyors a versatile solution for operations requiring reliability and productivity. By integrating pan conveyors into your facility, you can enhance throughput, reduce maintenance downtime, and optimize overall performance.

Pan conveyors are an indispensable tool for various industries, including cement manufacturing and power generation. Their ability to efficiently transport bulk materials, even under challenging conditions, makes pan conveyors a versatile solution for operations requiring reliability and productivity. By integrating pan conveyors into your facility, you can enhance throughput, reduce maintenance downtime, and optimize overall performance.

Innovation drives progress in every industry, and the world of conveyor technology is no exception. As businesses strive to maximize efficiency and productivity, advancements in conveyor systems are becoming essential. Beyond increasing profits, modernizing conveyors supports sustainability by reducing energy consumption and waste. In 2025, emerging conveyor technology trends promise to revolutionize the way industries handle bulk materials.

Innovation drives progress in every industry, and the world of conveyor technology is no exception. As businesses strive to maximize efficiency and productivity, advancements in conveyor systems are becoming essential. Beyond increasing profits, modernizing conveyors supports sustainability by reducing energy consumption and waste. In 2025, emerging conveyor technology trends promise to revolutionize the way industries handle bulk materials.