Pan Conveyors vs Drag Conveyors: Which Is Better for Bulk Solids?

Choosing the right system for bulk solids handling can improve performance, reduce downtime, and extend the life of your equipment. Two of the most widely used options in heavy-duty industrial settings are pan conveyors and drag conveyors. Each offers distinct benefits, depending on your material and operational needs.

Understanding the Basics

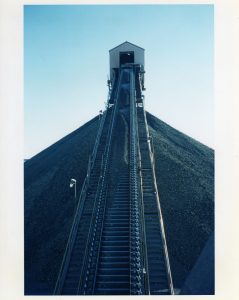

Pan conveyors use overlapping pans attached to a chain to carry materials forward. Known for their durability, they’re ideal for transporting hot, coarse, or abrasive materials like clinker or scrap metal in steel mills, cement plants, and foundries.

Drag conveyors move material by dragging it through a trough using flights or paddles. They are enclosed systems, making them a popular choice for handling dusty or fine materials such as ash, powders, or granules.

Material Type and Handling Needs

Different bulk solids call for different conveying approaches:

- Pan conveyors are built for heavy, high-temperature, or abrasive materials.

- Drag conveyors are more versatile for smaller, free-flowing, or hazardous materials.

Matching the conveyor to your material ensures safe, efficient operation.

Durability and Maintenance

Both systems are known for long service life, but maintenance needs vary:

- Pan conveyors are rugged and built to last in extreme environments, with easier access for inspection.

- Drag conveyors may wear more internally when handling abrasive materials, but their enclosed design helps protect components and reduce mess.

Understanding maintenance demands can help reduce costly downtime.

Dust Control and Containment

When handling fine or hazardous materials, dust control is critical:

- Drag conveyors offer a fully enclosed design to prevent dust from escaping.

- Pan conveyors are often open and less suited for applications where dust containment is essential.

If environmental compliance or cleanliness is a priority, drag conveyors are the better fit.

Space and Layout Flexibility

Your facility’s layout may influence your decision:

- Drag conveyors are compact and can move material in multiple directions or on inclines.

- Pan conveyors require more space and typically follow straight or slightly inclined paths.

For tight spaces or complex routing, drag conveyors provide more flexibility.

Energy Efficiency

Energy usage varies depending on material and application:

- Drag conveyors often operate at lower speeds and require less power over longer distances.

- Pan conveyors typically demand more robust drives due to heavier loads.

Considering energy needs can impact your long-term operational costs.

Which Conveyor Is Right for You?

There’s no one-size-fits-all answer. The right choice depends on your specific operation, material type, and performance goals.

Choose pan conveyors if:

- You handle hot, abrasive, or heavy materials

- You need superior durability in harsh environments

- Dust control is not a major concern

Choose drag conveyors if:

- You work with fine, dusty, or hazardous materials

- You need a fully enclosed, low-maintenance system

- Your site requires flexible routing or a compact footprint

Selecting the right conveyor ensures better flow control, fewer breakdowns, and long-term savings.

MHE Delivers Custom Conveyor Solutions

At Materials Handling Equipment (MHE), we design and manufacture both drag conveyors and pan conveyors tailored to your needs. Whether you’re transporting cement, ash, chemicals, or scrap, our systems are engineered for reliability, efficiency, and heavy-duty performance.

Let our experienced team help you select the right solution for your bulk solids handling challenges. Reach out today.

Pan conveyors are an indispensable tool for various industries, including cement manufacturing and power generation. Their ability to efficiently transport bulk materials, even under challenging conditions, makes pan conveyors a versatile solution for operations requiring reliability and productivity. By integrating pan conveyors into your facility, you can enhance throughput, reduce maintenance downtime, and optimize overall performance.

Pan conveyors are an indispensable tool for various industries, including cement manufacturing and power generation. Their ability to efficiently transport bulk materials, even under challenging conditions, makes pan conveyors a versatile solution for operations requiring reliability and productivity. By integrating pan conveyors into your facility, you can enhance throughput, reduce maintenance downtime, and optimize overall performance.

Innovation drives progress in every industry, and the world of conveyor technology is no exception. As businesses strive to maximize efficiency and productivity, advancements in conveyor systems are becoming essential. Beyond increasing profits, modernizing conveyors supports sustainability by reducing energy consumption and waste. In 2025, emerging conveyor technology trends promise to revolutionize the way industries handle bulk materials.

Innovation drives progress in every industry, and the world of conveyor technology is no exception. As businesses strive to maximize efficiency and productivity, advancements in conveyor systems are becoming essential. Beyond increasing profits, modernizing conveyors supports sustainability by reducing energy consumption and waste. In 2025, emerging conveyor technology trends promise to revolutionize the way industries handle bulk materials. Many industrial operations rely on bucket elevators to handle bulk materials efficiently. From moving materials vertically to transporting them across production lines, these systems are essential in industries like agriculture, mining, and manufacturing. However, choosing the right bucket elevator depends on your specific operational needs. Two common types are continuous and centrifugal bucket elevators, each offering unique advantages.

Many industrial operations rely on bucket elevators to handle bulk materials efficiently. From moving materials vertically to transporting them across production lines, these systems are essential in industries like agriculture, mining, and manufacturing. However, choosing the right bucket elevator depends on your specific operational needs. Two common types are continuous and centrifugal bucket elevators, each offering unique advantages.